Expansion Joint / Flexible Bellow / Compensator Fabric

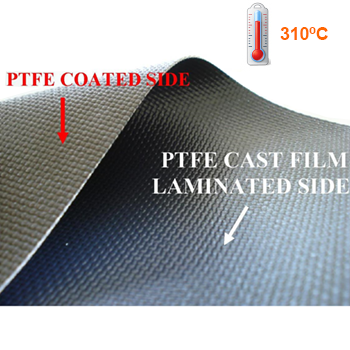

PTFE Coated Glass Cloth (Heavy Weight)

Expansion Joint & Flexible Bellow Fabrics for High-Temperature Movement Compensation

At Textile Technologies Europe Ltd, we supply a specialist range of coated technical fabrics designed for use in expansion joints, compensators, and flexible bellows.

These materials are engineered to withstand high temperatures, vibration, pressure fluctuations, and chemical exposure, making them ideal for sealing and isolating movement in industrial ducting, exhaust systems, and process equipment.

Our flexible joint fabrics combine mechanical strength with thermal resistance and chemical durability, suitable for both internal layers (gas sealing) and external layers (environmental protection) in multi-layer compensator systems.

Used by OEMs, fabricators, and maintenance teams in:

-

Power generation and flue gas systems

-

Petrochemical and refinery plants

-

Cement, steel, and glass manufacturing

-

HVAC and filtration systems

-

Marine, rail, and heavy industrial sectors

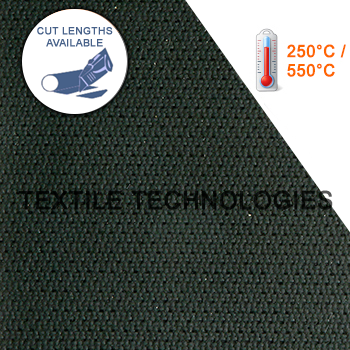

Our Range of Expansion Joint / Compensator Fabrics Includes:

-

Silicone Coated Glass Cloth (Standard & Supersil E Glass)

-

PTFE Coated Glass Cloth (Heavyweight & PTFE Cast Laminate)

-

Graphite Impregnated E Glass Cloth

-

Vermiculite Coated Glass and Silica Cloth

-

TRI-SIL Grey/Silver Glass Cloth

-

Neoprene Coated Glass Cloth (Including Antistatic Grade)

-

HT700 High-Temperature Glass Fabrics

-

Viton® Coated Glass Cloth

-

Vamac® Coated Glass Cloth

-

EPDM Coated Glass Cloth

These fabrics are available in rolls, cut lengths, or fabricated panels, with a variety of weights, thicknesses, coatings, and surface treatments to suit single- or multi-layer expansion joint designs.

What are expansion joint fabrics used for?

These technical fabrics are used in the construction of flexible expansion joints or bellows, which absorb movement caused by thermal expansion, vibration, or structural shifts in ducting and exhaust systems.

How do I choose the right coating?

-

Silicone: general-purpose high-temp sealing with good flexibility

-

PTFE: chemical-resistant and gas-tight, ideal for aggressive media

-

Graphite: low permeability and spark resistance

-

Viton®/Vamac®: superior chemical and weather resistance for flue gas lines

-

Neoprene: cost-effective with moderate temperature and weather protection

What temperatures can these fabrics withstand?

Depending on the base cloth and coating, our fabrics can handle continuous temperatures from 150°C to 1000°C, and even higher in layered compensators.

Can these be fabricated into finished expansion joints?

While we supply the technical fabrics, we also work closely with expansion joint manufacturers and can cut, layer, or prepare the fabrics to your project’s specifications or supply them in kit form.

Are antistatic or spark-resistant options available?

We offer graphite impregnated and antistatic neoprene-coated cloths for use in environments where electrostatic discharge or spark resistance is a concern.