High Temperature Sleeving for Thermal Protection

At Textile Technologies Europe Ltd, we supply an extensive range of manufactured high-temperature sleeving solutions designed to protect hoses, cables, pipes, and machinery in harsh industrial environments.

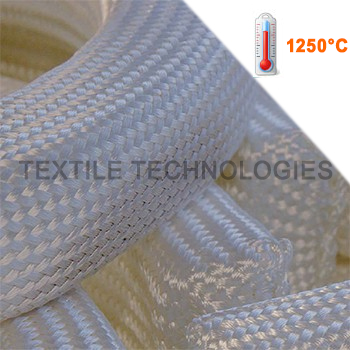

Our thermal sleevings are engineered using premium-grade fibres such as E Glass, HT750 Glass, Silica, Bio Soluble, Refractory Ceramic, Quartz, ALF Alumina, Stainless Steel, Para-Aramid, and BELCOTEX® 110.

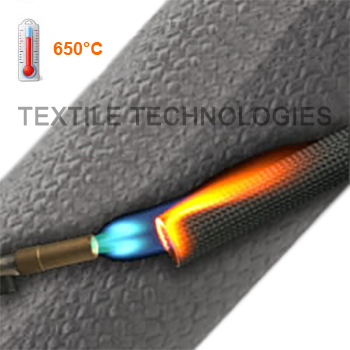

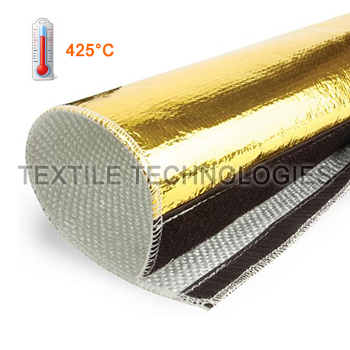

Available in woven, knitted, braided, or plaited constructions, each sleeving type offers unique combinations of heat resistance, flexibility, and in some instances abrasion tolerance, and mechanical protection where coatings like vermiculite have been applied.

Sleeves can also be coated, laminated, or impregnated with specialist materials for enhanced performance in molten splash, radiant heat, or high-friction conditions.

Our sleeving products are widely used by OEMs, fabricators, and maintenance teams operating in sectors such as:

-

Steel and Foundry

-

Glass and Ceramics

-

Automotive and Motorsport

-

Rail and Aerospace

-

Power Generation and Utilities

-

Marine and Shipbuilding

-

Industrial Manufacturing and Automation

Supplied in cut lengths subject to agreement, standard rolls, or custom stitched assemblies with options for Velcro closures, hook-and-loop wraps, and overlapping flaps for quick installation in retrofit environments.

What is high-temperature sleeving used for?

These sleevings are used to insulate and protect hoses, cables, and machinery from radiant heat, molten splash, mechanical abrasion, and chemical exposure. They’re common in exhaust systems, foundry lines, glass plants for roller coverings, electrical assemblies, and high-performance automotive or industrial environments.

What’s the difference between braided, knitted, and woven sleevings?

Each construction offers unique characteristics:

-

Braided: good flexibility and strength

-

Knitted: stretchable and easy to install

-

Woven: higher abrasion resistance but maintains a true tubular with no stretch.

-

Plaited: dense and heavy-duty

What temperature can these sleeves withstand?

Depending on the material, our sleevings can withstand continuous exposure from 250°C for Fire Sleeves (a special iron oxide silicone coated glass sleeve) all the way up to 1200°C+ for ALF alumina sleeving. Fire sleeve and some vermiculite coated options also offer molten metal splash protection.

Can I get sleeving with special coatings or closures?

Yes. We offer a wide range of coatings (silicone, foil, PU, vermiculite) and closure systems (Velcro, stitched flaps) for easy installation and added performance in specific environments.

Are your products compliant with safety and industrial standards?

Most of our thermal sleeving products meet or exceed EN, ISO, and industry-specific standards for heat resistance and safety. We can provide full documentation and performance data on request. If standards have not been established ask us about benchmarking where we test to set a benchmark expectation.

* BELCOTEX® is a registered trademark of BELCHEM GmbH, Germany.